3. Controllers & Dynamic Optimization

Written on June, 2025 by Bolton TranThis post in under construction.

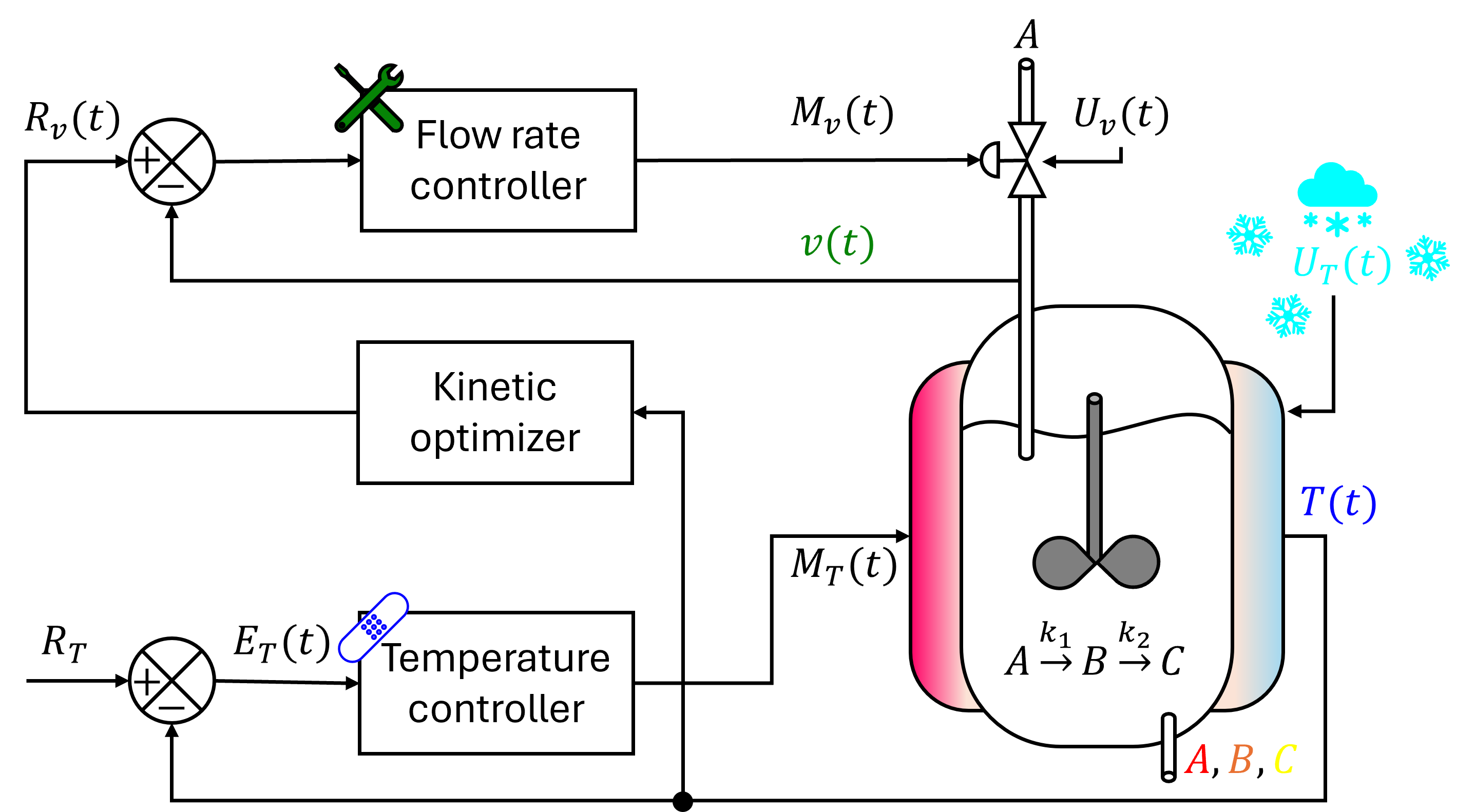

Plant settings:

1) A reaction in series is taking place in an ideal Continuous Stirred Tank Reactor (CSTR): $A \overset{k_1}{\rightarrow} B \overset{k_2}{\rightarrow} C$. The desired product $B$, of which concentration we want to maximize.

2) The reaction is endothermic, so we need to continuously heat the reactor to a constant temperature $T$.

3) The heater is “faulty”: at very cold ambient temperature ($U_T$), the controller gain drops by 90%.

4) A kinetic optimizer solves for the required volumetric flow rate $v$ of reactant $A$ so that product $B$ is continually maximized when the heater fails and reactor temperature drops.

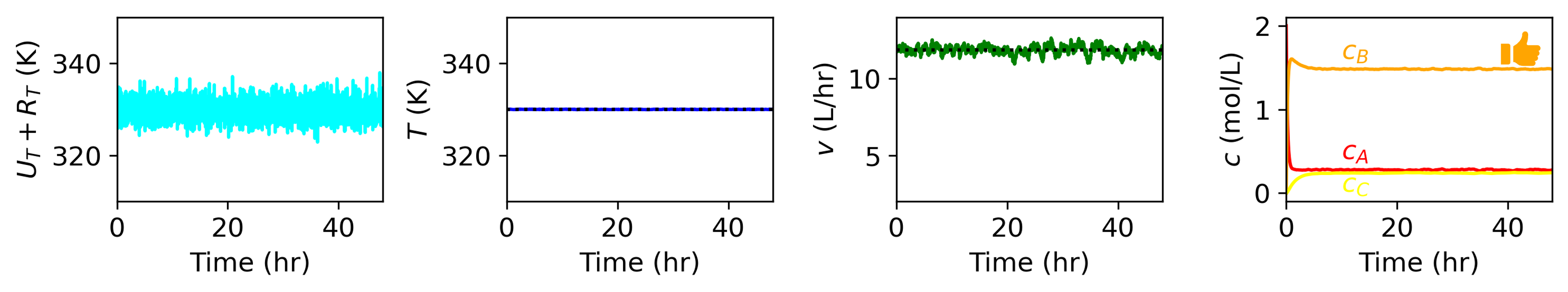

Scenario A: No temperature drops. System operates per usual. Concentration of $B$ is maxmized as desired.

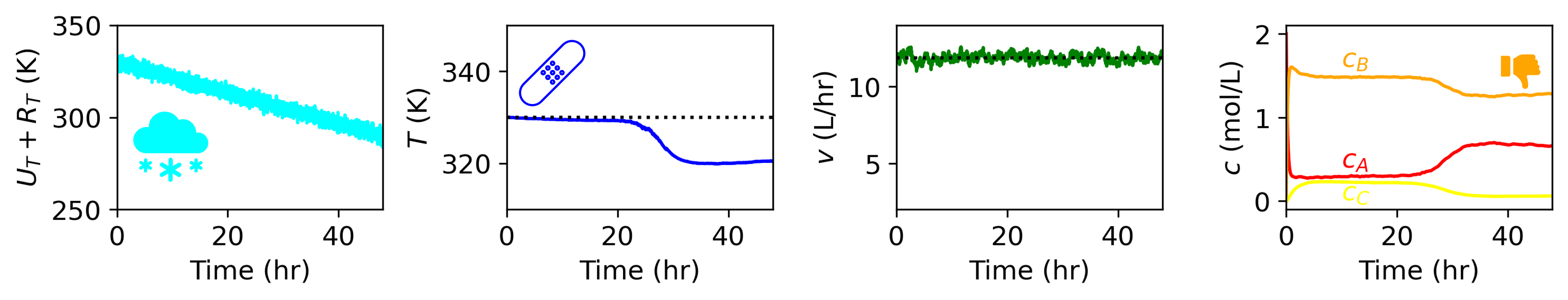

Scenario B: A WINTER STORM IS HERE!!! The temperature drops by 40 degrees over 2 days. Heater fails after a day. No correction to flow rate. Concentration of $B$ falls below desired.

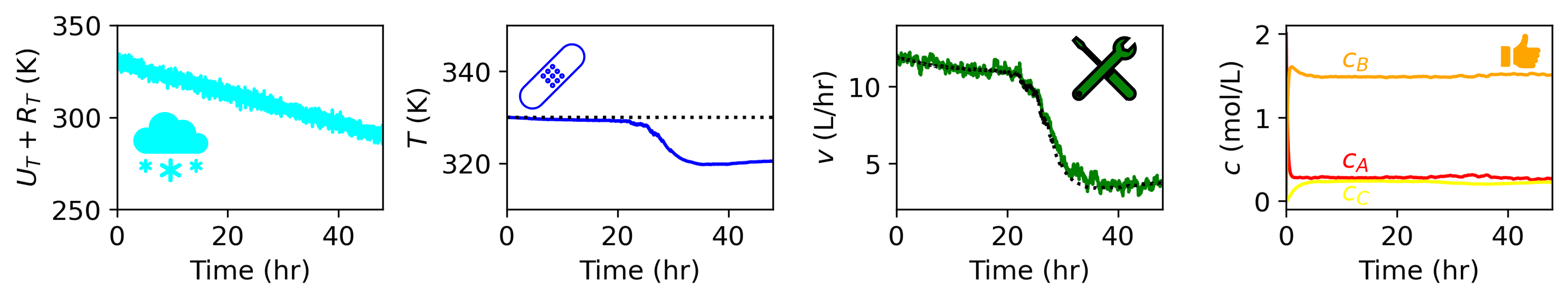

Scenario C: Temperature drops and heater fails as above. Flow rate setpoints are dynamically adjusted through the kinetic optimizer. Concentration of $B$ stays as desired.

Python code: More explanation coming soon

import numpy as np

import matplotlib.pyplot as plt

from scipy.optimize import fsolve

from scipy.integrate import solve_ivp

from scipy.interpolate import interp1d

from scipy.optimize import minimize_scalar

#Constants

kB=8.3144/1000 #kJ/mol.K

h=4.135667696E-15*96.49/3600 #kJ/mol.h

EA1=100 #kJ/mol

EA2=110 #kJ/mol

vol=20 #L

cA0=2 #M

#Optimize flowrate based on reaction kinetics

def ststB(v, T):

#Rate constants

k1=(kB*T/h)*np.exp(-EA1/kB/T)

k2=(kB*T/h)*np.exp(-EA2/kB/T)

#residence time

tau=vol/v

#Define ODEs

def stst(c):

#c is array for concentrations

cA=c[0]; cB=c[1]; cC=c[2]

dcAdt=cA0/tau - cA/tau - k1*cA

dcBdt=-cB/tau + k1*cA - k2*cB

dcCdt=-cC/tau + k2*cB

return [dcAdt, dcBdt, dcCdt]

#Solve st st ODE

cs=fsolve(stst, [cA0,0,0] )

return -cs[1] #minus change minimize to maximize

#Run optimization

temps=np.arange(250, 402, 2)

optv=[minimize_scalar(ststB, bounds=(1,20), args=(i), method='bounded').x for i in temps]

#Interpolate

vopt_temp=interp1d(temps, optv)

##-----Time setup-----

tmax=48

dt=1/60

time=np.arange(0, tmax+dt, dt)

##----- Set up temperature controller-----

tauT=5 #temp time constant

KpT=10 #proportional gain

KiT=1 #integral gain

T0=330 #intial temperature

MT0=T0

##Set point

RT=np.zeros(len(time))+T0

#Load fluctuation

UTramp=np.linspace(0,-40,len(time))

UTfluc=np.array([np.random.normal(loc=0, scale=2) for i in range(len(time))])

UT=UTfluc+UTramp

#initialize arrays

T=np.zeros(len(time))

ET=np.zeros(len(time))

MT=np.zeros(len(time))

#Initial C

T[0]=T0

#Intial E

ET[0]=RT[0]-T0 #error

EiT=ET[0]*dt #integral error

#Initial M

MT[0]=KpT*ET[0] + KiT*EiT + MT0 #PID logic with offset

#Initial derivatives

dT=(-T[0] + MT[0] + UT[0])/tauT

##----- Set up flow rate controller -----

tauv=2

Kpv=5 #proportional gain

Kiv=1 #integral gain

v0=vopt_temp(T0) #intial

Mv0=v0 #same manipulated variable as offset

##Set point and load

Rv_fixed=np.zeros(len(time))+v0 #set C0

Rv_opt=np.zeros(len(time))+v0

#Load fluctuation

Uv=np.array([np.random.normal(loc=0, scale=10) for i in range(len(time))])

##-----Set up numerical solver-----

#initialize arrays

v=np.zeros(len(time))

Ev=np.zeros(len(time))

Mv=np.zeros(len(time))

#Initial

v[0]=v0

#Intial E

Ev[0]=Rv_fixed[0]-v0 #error

Eiv=Ev[0]*dt #integral error

#Initial M

Mv[0]=Kpv*Ev[0] + Kiv*Eiv + Mv0 #PID logic with offset

#Initial derivatives

dv=(-v[0] + Mv[0] + Uv[0])/tauv

##------Intialize reactor-------

cA=np.zeros(len(time))

cB=np.zeros(len(time))

cC=np.zeros(len(time))

cA[0]=2

cB[0]=0

cC[0]=0

k1=np.zeros(len(time))

k2=np.zeros(len(time))

k1[0]=(kB*T[0]/h)*np.exp(-EA1/kB/T[0])

k2[0]=(kB*T[0]/h)*np.exp(-EA2/kB/T[0])

tauR = vol/v[0]

dcA=cA0/tauR - cA[0]/tauR - k1[0]*cA[0]

dcB=-cB[0]/tauR + k1[0]*cA[0] - k2[0]*cB[0]

dcC=-cC[0]/tauR + k2[0]*cB[0]

##-----Solve=propagrate through time-----

for t in range(1,len(time)):

#Solve temperature controller logic

T[t]=T[t-1]+dT*dt

ET[t]=RT[t]-T[t] #error

EiT+=ET[t]*dt #cumulate integral error

#Constrain controller gain based on load

if UT[t]>-20:

KpT=10 #proportional gain

KiT=1 #integral gain

else:

KpT=10/10 #proportional gain

KiT=1/10 #integral gain

MT[t]=KpT*ET[t] + KiT*EiT + MT0 #PI logic with offset

dT=(-T[t] + MT[t] + UT[t])/tauT

#Solve flowrate controller logic

v[t]=v[t-1]+dv*dt #update from previous step

#Ev[t]=Rv_fixed[t]-v[t] #error based on fixed setpoint

Rv_opt[t]=vopt_temp(T[t])

Ev[t]=Rv_opt[t]-v[t] #error based on dynamic setpoint

Eiv+=Ev[t]*dt #cumulate integral error

Mv[t]=Kpv*Ev[t] + Kiv*Eiv + Mv0 #PI logic with offset

dv=(-v[t] + Mv[t] + Uv[t])/tauv

#Solve reactor kinetic

cA[t]=cA[t-1]+dcA*dt #update from previous step

cB[t]=cB[t-1]+dcB*dt

cC[t]=cC[t-1]+dcC*dt

k1[t]=(kB*T[t]/h)*np.exp(-EA1/kB/T[t])

k2[t]=(kB*T[t]/h)*np.exp(-EA2/kB/T[t])

tauR = vol/v[t]

dcA=cA0/tauR - cA[t]/tauR - k1[t]*cA[t]

dcB=-cB[t]/tauR + k1[t]*cA[t] - k2[t]*cB[t]

dcC=-cC[t]/tauR + k2[t]*cB[t]

#----Plot-----

fig, axes=plt.subplots(1,4, figsize=(10,2),dpi=300)

axes[0].plot(time, UT+RT, c='cyan')

axes[0].set_ylim(250, 350)

axes[0].set_ylabel(r'$U_T + R_T$ (K)', fontsize=12)

axes[1].plot(time, T, c='b')

axes[1].plot(time, RT, ls=':', c='k')

axes[1].set_ylim(310, 350)

axes[1].set_ylabel(r'$T$ (K)', fontsize=12)

axes[2].plot(time, v, c='g')

#axes[2].plot(time, Rv_fixed, ls='--',c='k')

axes[2].plot(time, Rv_opt, ls=':',c='k')

axes[2].set_ylim(2, 14)

axes[2].set_ylabel(r'$v$ (L/hr)', fontsize=12)

cABC=[cA, cB, cC]

colors=['r', 'orange', 'yellow']

[axes[3].plot(time, cABC[i], c=colors[i]) for i in range(3)]

axes[3].set_ylabel(r'$c$ (mol/L)', fontsize=12)

axes[3].annotate(r'$c_A$', xy=(10, 0.4), color='r', fontsize=12)

axes[3].annotate(r'$c_B$', xy=(10, 1.6), color='orange', fontsize=12)

axes[3].annotate(r'$c_C$', xy=(10, 0.01), color='yellow', fontsize=12)

[i.set_xlim(0,48) for i in axes]

[i.set_xlabel('Time (hr)', fontsize=12) for i in axes]

[i.tick_params(labelsize=12) for i in axes]

plt.tight_layout()

plt.show()